What People Are Saying About Eco-Panels

Prospective Client from New York State

“Thanks! This is fantastic! This is the kind of info I’m looking for. We are indeed looking at that lower side of the custom home market and I love the simplicity of have the zip on the outside for speed and efficiency. I also love the ability to hand set these since we are sort of weekend warriors (ex pro carpenters who got desk jobs). Speed and efficiency of assembly is critical to my goals for these builds. We’re looking at … panelized wall systems and potentially roof or partial and trusses on what we can’t panelize.”

Folly Beach, South Carolina Owner Very Pleased with Eco-Panels Performance

I just wanted to send you a quick note thanking you and Eco-Panels for your fine products and service. Each day building a custom home brings a new supply chain issue, price hike, or set back in today’s world. Eco-Panels delivered what they promised, when they promised it, and at the price they quoted. If you ever need to send a potential buyer/home owner by my place on Folly [Beach, South Carolina], just let me know. Please thank everyone at Eco-Panels for me and let them know how much I appreciate their fine work and commitment to their customers.

Solamente queria mandar esta nota rapida agradeciendole a usted y a Eco-Panels por su excelente producto y servicio. Cada dia la construccion de una casa personalizada trae consigo un nuevo problema en la cadena de suministro, un aumento de precio o un retroceso en el mundo actual. Eco-Panels entrego lo que prometio cuando lo prometio y al precio que indico. Si alguna vez nesecita enviar a un possible comprador/propetario de casa a mi casa en Folly [Beach, Carolina del Sur], hagamelo saber. Porfavor, agradezca a todos en Eco-Panels de mi parte y Hagales saber cuanto aprecio su excelente trabajo y compromiso con sus clientes.

Real Estate Investor client in Western North Carolina:

It was probably 95 degrees outside today – we don’t even have power to the build site yet – and I step inside the Eco-Panels home and it feels like its 20 degrees cooler. Its hard to believe!

[EP note: Just like with much of the country, while it can get very hot in the peak 3-4 hours in a day, it can easily fall 25 or 30 degrees at night. A home protected with Eco-Panels will tend to maintain an interior temperature very close to the daily average temperature – in this case in the mid-to upper 70s – even when it is “darn hot!” on the outside. Stud framed homes can never do this because of all the thermal bridging inherent in the system – the studs are like coils of a radiator heating the interior of a home.]

C.G. in Kentucky – “Most Energy Efficient Home In Kentucky”

Wanted to give everyone an update and let you know how pleased we are with the new house. We had a blower door test last week (our last one of three) and we were called and told that at the present time we had the most energy efficient home in KY. We expect to get some kind of certificate. Thanks to everyone for all their help!

Resort Development Manager, St. John, U.S. Virgin Islands, After Hurricane Irma, 2017

Your [Eco-Panels] buildings – the buildings made with Eco-Panels – were the ONLY buildings not structurally damaged by Hurricane Irma. Every other building we have – whether stud framed or made from stone or brick – were either partially or entirely destroyed and are all no longer usable. Except for the buildings made from Eco-Panels.

[EP note: The weather station on St. John during Hurricane Irma was destroyed during the storm and the highest wind speed recorded before it was destroyed was 185 mph. It is thought that in some places winds – strong enough to destroy stone & mortar buildings with a steel frame roof – exceeded 200 mph.]

Owner-Builder Client Tom from Greenville, South Carolina Area

Good to hear from you Charles. Love the new look to your site. Here are a few words that may be helpful – use what you think best.

When we first contacted Eco-Panels, we were looking for control of utility costs, noise reduction, and a solid, stable building structure; between Eco-Panels and our HVAC contractor, we got more than expected and are thrilled with the results.

First, Eco-Panels manufacturing process, particularly the use of polyurethane in their product [with virtually no studs that would otherwise promote energy loss], produces an outstanding envelope for our house. In stick-built homes the corners are required to have a special nailing pattern to produce what is called a stress panel, so they only have that on the corners to create strength in the building envelope. Eco-Panels are stress panels throughout (every panel) for a superior structure. Very quiet; tight insulation results in low utility costs. We also chose to have ZIP panels for an exterior and Eco-Panels delivered.

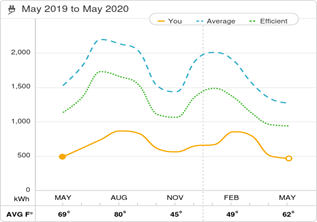

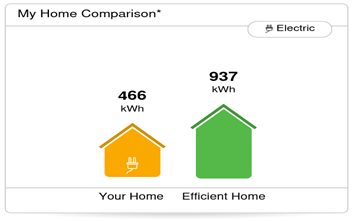

In South Carolina, we electrically heat and air condition 4,400 square feet with a Trane 2-ton variable speed heat pump with a Trane variable speed air handler 2 zone HVAC system; although a two-zone system, we almost never run the second zone – the basement stays an even temperature without additional conditioning. Our electric costs are less than $94.00 per month average (see Duke Energy graphics below, which show fairly stable usage throughout the year).

What I can tell anyone interested, is that we got more than we asked for. The combination of Eco-Panel SIPs and a knowledgeable HVAC contractor gave us the results we were looking for.

[EP Note: Tom is a professional handyman and either did the work himself or hired his own plumber, electrical or siding contractors to help him build his 4,400 sqft home at a cost of less than $110/sqft. Tom’s home with Eco-Panels uses less than half the electricity that Duke Energy expects of an “efficient home”. That’s almost like Duke Energy is paying Tom for his good decisions!]

International Disaster Relief Contractor:

We researched more than 100 panel companies in the United States, Canada, China and South Korea for our project. Only Eco-Panels had all the elements that we needed to make our project … successful. We need a structure that can go up quickly with low-skilled labor. We need a product that is basically complete because we can not obtain anything locally. The harsh climate … requires extreme thermal efficiency for both hot humid summers and cold windy winters. Eco-Panels does a remarkable job of meeting those requirements. All the people at Eco-Panels understand their product and understand their customers’ needs and are great to work with.

Joe – Raleigh, North Carolina

Our home is amazing, and continues to be so! I can’t imagine living in anything other than an Eco-Panels home. Thanks again, and everything continues to perform well for us.

[EP note: Joe built his house 10 years ago. After all costs and savings from different sources are considered, he figures he built his home for the same cost as stud frame with spray-foam insulation. But his home is bigger than his last one and his energy bills are much less.]

M.T., near Black Mountain, North Carolina

“I am very happy with my energy bills 🙂 in fact Duke Power sends me an energy audit every month and this house is always the most efficient in my area! When the weather improves and I can get my outside areas back together I would be happy to send some pics.”

[Eco-Panels note: we always try to maintain a relationship with clients, hoping to understand their energy bills, assist them if things don’t go well, answer questions if they are doing renovations, provide information and assistance if they are looking to sell their home, get pictures of the finished house, etc., etc.]

Jesse T. – Union, Connecticut

(Just after they received their Certificate of Occupancy (CO)) –

“We are moved in and have our CO. We actually hosted Thanksgiving there! We have no idea how the house is performing (no propane or electric bill yet despite being hooked to the grid for almost 4 months!) but it is super comfortable! Everyone that comes always tells us how ‘warm’ it is, with the thermostat set to 68º. So far we are very happy, interested to see what the first propane fill-up looks like, I haven’t even had time to look at the gauge yet. We have a 500 gal underground tank feeding a Viessmann condensing boiler with low temp radiant; because the house is so tight I’ve been monitoring water temps and with few exceptions, the boiler is constantly circulating 80-85º water, just enough for warm toes. I had a lot of people tell me that radiant is a waste in a high-performance home but we love it (placed in selective places around the house, bathrooms, and high traffic main areas). With the tightness of the house, I did not even bother to put any heat source in the outlying separate rooms of the house and seems evenly distributed. We haven’t gotten the upstairs heat hooked up yet (except radiant in bathrooms) and it still stays warm up there on 20º nights, About ~65ºF. SPF Insulated attic stays at around 60ºF with no heat source. Currently, no ERV (researching and saving up for one- rough ducting for it is in place- suggestions welcomed, thinking either venmar/Broan or Panasonic) but have continuous run Panasonic bath fans for now and the house does not feel stuffy. We did have some window condensation issues at first but I’m running a dehumidifier in the basement until ERV install and seems to have taken care of that (before the dehumidifier we were at 65%RH!) – still a little on really cold mornings. I assume a lot of that is construction moisture (rainy spring/summer) and there are a lot of green lumber from timber frame drying and the concrete in basement shedding its water. The garage is ridiculously warm and on its own zone at 60ºF. It barely ever runs. Only when a door is open.”

“BTW, preassembling the gable ends onto a truss with soffit pre-built and then swinging the whole thing in as one piece worked absolutely awesome. To date, I have only ripped one 1/2″ piece off a final piece going into a corner and a couple of blade widths on some headers/footers when assembling this entire house. The fit of the panels is really stunning. I’m sheathing the roof today.”

[EP note – our corner panels have the ability to trim or “stretch” length of the wall to address potential issues with floor platform being different dimension – that is what he is referring to.]

Harriet, Snow Camp, Alamance County, North Carolina

Client message from winter during DIY construction:

“We are a week or two from moving in. Actually, when it went down to 4 degrees, [instead of staying in the RV] we moved into the back bedroom to avoid the RV. Our conclusions about EcoPanel have been made. After installing a wood heater, we have had the house at about 65 degrees, even in the most severe cold. [Sealant foam].. and the panels made it all happen. The system is, as we expected, incredible. You get five stars. Smartest thing we ever did.”

Follow-Up message from same client in late June:

“Our first electricity bill was $43. We open the windows at night, close them at 8am, and the house stays in the low 70’s all day. Have turned on the a/c once. …. Can’t think of a single negative.”

J.B., Sherrill’s Ford, North Carolina

“My son is a builder, and he talked me out of using your panels for our home. He could do it better, he said. Now that the home is built, I wish I had NOT listened to him – and I wish I had built with Eco-Panels. Funny thing is, now that he knows more about your product, he wishes he had built our home out of your panels too. In the future I will recommend my friends building their homes to look seriously at Eco-Panels.”

D.H., Certified Public Accountant (CPA), south of San Antonio, Texas

“….Just wanted to say out of all the panel companies I talked to and considered, your group was the most helpful and responsive… The only thing I did was do a lot of reading on the internet and in the forums. A lot of folks spoke of their performance from their sip homes. One factor was thermal bridging and on my last house from experience fiberglass just doesn’t cover all the voids. Also corners were another void which was hard to insulate especially the way framers tend to build them. Your corners is what caught my attention. I did put the pencil to it to figure a studded house with polyurethane foam, zip panel and foam on the outside and there really wasn’t any savings [in building stick-frame]. Plus having to watch all the trades. I have a friend who has been watching what I’m doing and has been surprised at how sturdy the walls are. He wanted me to build with stick but I planned this way too long to deviate. My ex-wife’s cousin’s husband had to rebuild their sausage plant freezer and it’s just all foam with steel frame for the door. So it makes sense. I will say since this was my first sip project I did shop around especially since I was unfamiliar with all the technical details. Some made their products sound really good but then couldn’t explain what they needed. Your company was very helpful throughout and as I’ve always said service is the key. Next time or if someone wants a recommendation I would have to refer them to ecopanels. Save yourself time and the headache and just go directly to y’all. Sorry got long winded. I’ll keep you updated”

[EP note: he will passively cool his house by building a super-insulated building envelope directly on an uninsulated concrete slab – keeping it cool in the heat of the summer!]

Lynn, Weaverville, North Carolina

“My energy bills average $100 less every month than any of the other homes on my street!”

[EP note: Lynn’s 1,300 sqft home built in 2011 (with Eco-Panels wall panels only!) averages energy bills of $100 less than any other home on the street with similar number of occupants and size (approx 6 of them).]

Tim, from West End / Southern Pines area, North Carolina

“Eco-Panels provided my exterior walls and I just love them. The house is “energy tight” and quiet. I am still amazed at how close the fit and precision was. I give you a high recommendation whenever I can.”