Good to hear from you Charles. Love the new look to your site. Here are a few words that may be helpful – use what you think best.

When we first contacted Eco-Panels, we were looking for control of utility costs, noise reduction, and a solid, stable building structure; between Eco-Panels and our HVAC contractor, we got more than expected and are thrilled with the results.

First, Eco-Panels manufacturing process, particularly the use of polyurethane in their product [with virtually no studs that would otherwise promote energy loss], produces an outstanding envelope for our house. In stick-built homes the corners are required to have a special nailing pattern to produce what is called a stress panel, so they only have that on the corners to create strength in the building envelope. Eco-Panels are stress panels throughout (every panel) for a superior structure. Very quiet; tight insulation results in low utility costs. We also chose to have ZIP panels for an exterior and Eco-Panels delivered.

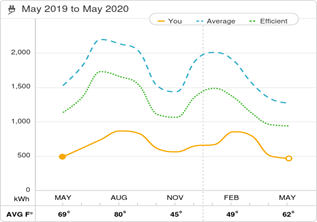

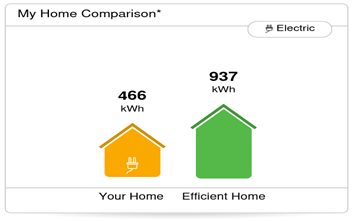

In South Carolina, we electrically heat and air condition 4,400 square feet with a Trane 2-ton variable speed heat pump with a Trane variable speed air handler 2 zone HVAC system; although a two-zone system, we almost never run the second zone – the basement stays an even temperature without additional conditioning. Our electric costs are less than $94.00 per month average (see Duke Energy graphics below, which show fairly stable usage throughout the year).

What I can tell anyone interested, is that we got more than we asked for. The combination of Eco-Panel SIPs and a knowledgeable HVAC contractor gave us the results we were looking for.

[EP Note: Tom is a professional handyman and either did the work himself or hired his own plumber, electrical or siding contractors to help him build his 4,400 sqft home at a cost of less than $110/sqft. Tom’s home with Eco-Panels uses less than half the electricity that Duke Energy expects of an “efficient home”. That’s almost like Duke Energy is paying Tom for his good decisions!]

Recent Comments