The NAHB recently recognized Eco-Panels as one of the most innovative start-ups in the construction industry for our new product invention, an insulated concrete block called the EPIC Block (article here).

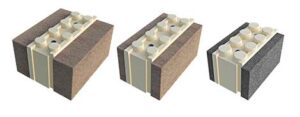

This new product is comprised of two “skins”/facers of concrete (or other suitable composite materials) bonded together by very strong/durable closed cell urethane foam having a bonding strength of greater than 8,000 PSF per side. The outer skins carry the vertical loads, much like a sandwich panel. Load bearing capacity is limited only by the size and compressive strength of the material chosen for “skins” of the block, so hundreds of thousands of pounds load bearing capacity is possible. The wall can be fully insulated and electrically chased upon completion. Embedded sensors within the intelligent EPIC Blocks can relay information regarding building conditions relating to temperature of interior or exterior, moisture content, change in location relative to other Blocks, etc

bonded together by very strong/durable closed cell urethane foam having a bonding strength of greater than 8,000 PSF per side. The outer skins carry the vertical loads, much like a sandwich panel. Load bearing capacity is limited only by the size and compressive strength of the material chosen for “skins” of the block, so hundreds of thousands of pounds load bearing capacity is possible. The wall can be fully insulated and electrically chased upon completion. Embedded sensors within the intelligent EPIC Blocks can relay information regarding building conditions relating to temperature of interior or exterior, moisture content, change in location relative to other Blocks, etc

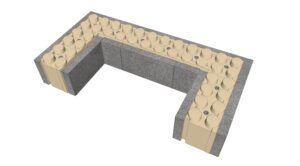

In a world of increasingly fewer skilled masons, non-skilled workers can easily assembled them by dry-stacking or bonding with urethane adhesives. It is our desire to keep concrete products in play in the building industry – for their strength and durability – but now in a

durability – but now in a  super-insulated block form (the blocks shown here are rated at R40). This Block can use 60-80% LESS concrete & cement and have significantly lower carbon emissions than concrete walls typically have had yet for government or community buildings like schools the concrete sides offer all of the safety and durability that concrete structures have offered in the past. Seismic configurations of this product offering are also under development. US and International Patents Pending.

super-insulated block form (the blocks shown here are rated at R40). This Block can use 60-80% LESS concrete & cement and have significantly lower carbon emissions than concrete walls typically have had yet for government or community buildings like schools the concrete sides offer all of the safety and durability that concrete structures have offered in the past. Seismic configurations of this product offering are also under development. US and International Patents Pending.

Recent Comments